Automatic sorting solutions have become increasingly important in modern production lines, particularly for industries handling delicate or varied products. WEIGHT SORTING offers equipment that streamlines this process efficiently. Their weight grader systems are designed to categorize items based on weight, reducing manual labor and improving consistency across batches. By utilizing automated mechanisms, products are guided through sorting stages with minimal human intervention, which helps maintain uniformity and reduces handling errors.

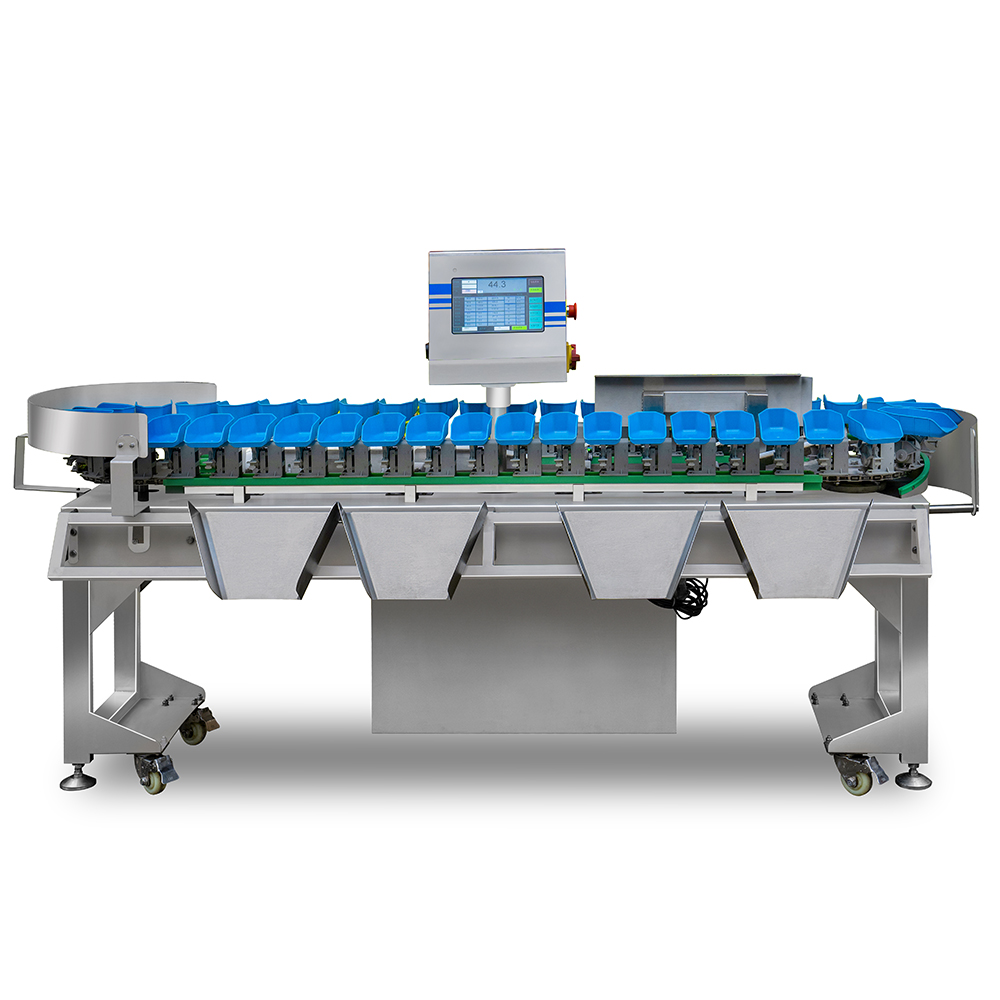

Rotating Trays for Versatile Product Handling

The rotating trays in WEIGHT SORTING’s weight grader simplify the sorting process by adapting to different product characteristics. These trays allow the machine to handle softer, thinner, or more viscous items without causing damage or misclassification. The movement is smooth, ensuring products are directed accurately to the appropriate output channels. This approach also reduces the risk of product jams, contributing to a more reliable and continuous operation, even in busy production environments.

Durable and Waterproof Design Enhances Reliability

Another aspect of the weight grader from WEIGHT SORTING is its robust design. The machines are built to withstand humid and demanding industrial conditions, providing durability and extended service life. Additionally, the waterproof construction allows for easier cleaning and maintenance, which is crucial for industries like food processing. Precision sensors in the system ensure that each item is measured accurately, maintaining weight consistency with a typical tolerance of ±0.3g.

Enhancing Efficiency in Production Lines

By integrating these automatic weight grader systems, businesses can optimize their sorting workflows without compromising on accuracy. WEIGHT SORTING provides equipment that balances gentle handling with precise measurement, making it suitable for a wide range of products. Their solutions contribute to smoother operations, reduce errors, and allow companies to focus on other aspects of production. With reliable technology and thoughtful design, these systems support more organized and efficient manufacturing processes.