Table of Contents

At SoonSer, they believe that SLA 3D printing is transforming the landscape of modern manufacturing. As an industry leader in SLA 3D printer technology, SoonSer is helping companies achieve higher precision and faster production times. SLA 3D printing involves the use of ultraviolet light to cure liquid resin, layer by layer, which is then solidified to create intricate and highly detailed models. With advanced machines like the SoonSer SLA 3D printer, manufacturers can accelerate product development, reduce waste, and ensure that every part is produced to the highest standards.

The Process Behind SLA 3D Printing

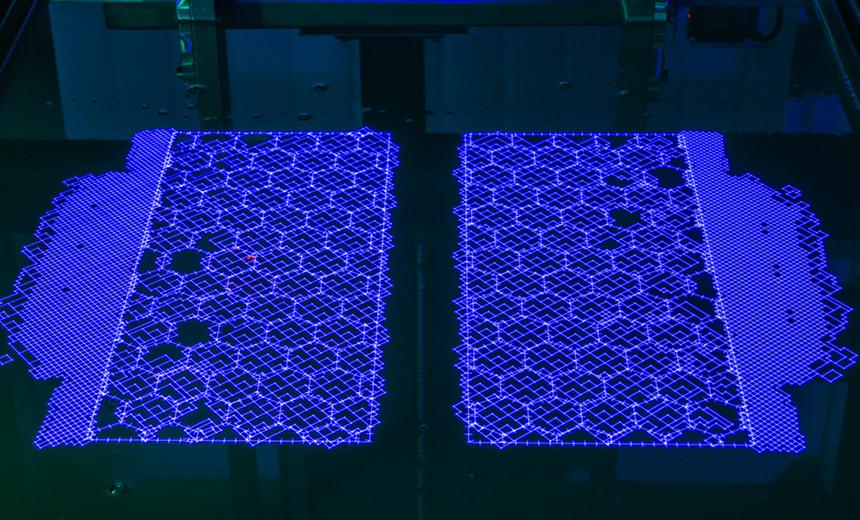

SLA 3D printing uses a laser or light source to cure liquid resin into solid layers, creating complex 3D models with high precision. The process starts with the design of the model, which is sliced into thin layers using 3D modeling software. The printer then starts to cure the first layer of resin using UV light, solidifying it according to the digital design. Once the first layer is complete, the build platform lowers slightly, and the next layer is cured on top of it. This process repeats until the entire object is built up, layer by layer.

SoonSer’s SLA 3D printers are designed for maximum accuracy, enabling manufacturers to produce highly detailed parts, prototypes, and end-use products. Unlike traditional manufacturing methods that require molds or tooling, SLA technology allows companies to create intricate geometries that would otherwise be impossible or extremely costly to achieve. The ability to produce parts with high resolution and minimal finishing requirements is one of the key reasons SLA 3D printing is becoming a preferred choice in industries such as automotive, medical devices, and jewelry. With SoonSer’s SLA 3D printers, manufacturers can produce detailed, high-quality parts faster and more cost-effectively than ever before, accelerating their time-to-market and ensuring top-tier quality in every production run.

Key Advantages of SLA 3D Printing for Manufacturing

One of the major advantages of SLA 3D printing is its ability to produce highly detailed, high-resolution parts. Unlike traditional methods like injection molding or CNC machining, which may require significant tooling and setup, SLA 3D printers can produce parts directly from digital designs without the need for molds. This not only speeds up the production process but also drastically reduces the cost of making small batches of custom or prototype parts.

SoonSer’s SLA 3 D printers excel in producing fine details with high accuracy, ensuring that every part is consistent and precise. This is especially beneficial for industries such as automotive or medical devices, where precision is critical. Whether creating functional prototypes for testing or producing small volumes of custom parts, the ability to directly produce detailed parts with SLA 3D printing leads to faster iteration, less material waste, and lower production costs. For industries that require bespoke or limited-run products, SLA 3D printing with SoonSer’s advanced printers offers an affordable and efficient solution. With the capability to create highly accurate models and parts in record time, companies can be more agile in their operations and better serve the unique demands of their customers.

Enhancing Production Speed and Flexibility with SLA 3D Printing

In addition to precision, SLA 3D printing offers significant advantages in terms of production speed and flexibility. Traditional manufacturing methods often require long setup times for tooling and molds, making it difficult to adjust designs quickly or produce small quantities cost-effectively. With SLA technology, manufacturers can produce prototypes or parts on-demand, cutting down on lead times and reducing the need for large-scale production runs.

SoonSer’s SLA 3D printers allow companies to produce parts in a fraction of the time it would take with conventional methods, significantly improving production efficiency. The flexibility to produce small batches or one-off custom parts enables manufacturers to meet the demands of niche markets or respond quickly to design changes. Whether it’s creating prototypes for testing or manufacturing small quantities of parts for end-use, SLA 3D printing helps businesses stay agile, reduce costs, and accelerate their time-to-market. This ability to produce high-quality, low-volume parts quickly makes SLA 3D printing a valuable tool for industries like aerospace, automotive, and healthcare, where fast turnaround times are crucial for success.

Conclusion

SLA 3D printing is reshaping how products are designed, prototyped, and produced. By offering exceptional precision, speed, and flexibility, SoonSer’s SLA 3D printers are enabling businesses to innovate faster and reduce production costs. With SLA technology, manufacturers can produce detailed prototypes, low-volume parts, and custom products without the need for expensive molds or long setup times. Whether for rapid prototyping, small-batch production, or mass customization, SLA 3D printing is becoming an essential tool for industries looking to stay competitive in a fast-evolving market. As SoonSer continues to push the boundaries of 3D printing technology, businesses can count on their cutting-edge solutions to stay ahead of the curve. Embracing SLA technology is not only about improving current processes; it’s about preparing for the future of manufacturing, where speed, quality, and customization are the keys to success.