Lithium battery automation equipment plays a crucial role in enhancing production efficiency and maintaining quality in battery manufacturing. As the demand for lithium batteries continues to grow—driven by applications in electric vehicles, renewable energy storage, and portable electronics—manufacturers must invest in advanced automation technologies. Understanding the key features of this equipment is essential for companies looking to optimize their production lines.

Enhanced Coating Solutions

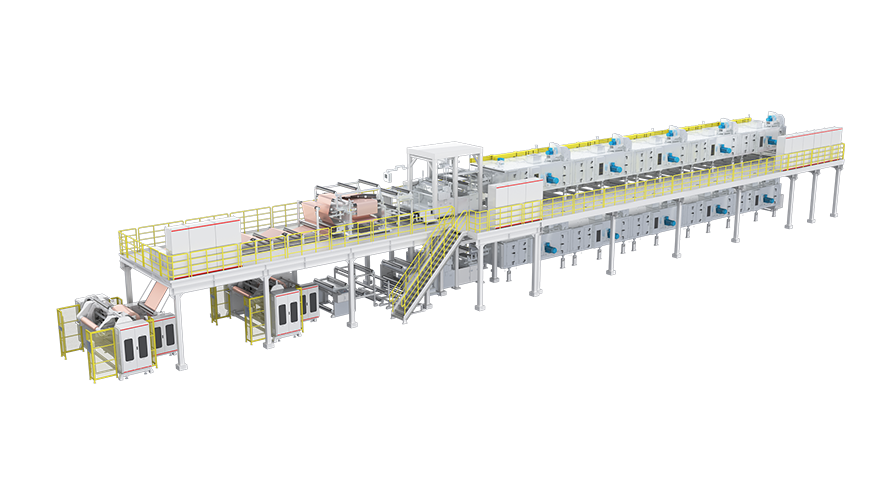

At the heart of lithium battery manufacturing lies the coating process, which is vital for electrode performance. Advanced lithium battery automation equipment, such as the double-layer super-E coating machine, offers innovative solutions that surpass traditional models. This new E-shaped electrode layout allows electrodes to undergo two drying processes within a single oven—enhancing efficiency by reducing the overall length of the process by over 35%. This innovation not only accelerates production but also optimizes space and energy consumption.

Improved Efficiency and Reduced Footprint

One of the standout features of modern lithium battery automation equipment is its ability to maximize productivity while minimizing resource use. The double-layer super-E coating machine, for instance, doubles the oven efficiency and reduces energy consumption by more than 35%. By decreasing the equipment footprint by 35% and lowering the floor space needed for battery cell plants by 8%, manufacturers can streamline their operations and reduce overhead costs, making their production lines more adaptable and efficient.

Integration with Smart Technologies

The latest lithium battery automation equipment incorporates smart technology and data analytics to enhance monitoring and control during production. These advancements enable manufacturers to collect real-time data, ensuring quality control and allowing for immediate adjustments to processes. Such integration improves consistency and reliability, ultimately contributing to higher-quality batteries and reducing waste in the manufacturing process.

Elevate Your Production with Yinghe’s Innovations

Understanding the key features of lithium battery automation equipment is essential for businesses aiming to stay competitive in the evolving battery market. Yinghe stands out as a leader in providing cutting-edge solutions tailored for lithium battery manufacturing. With innovations like the double-layer super-E coating machine, Yinghe empowers manufacturers to enhance their production capabilities, achieve significant energy savings, and optimize their manufacturing environments. Partnering with Yinghe means leveraging high-performance lithium battery automation equipment to lead in a fast-growing industry.